Products

Vertical cold bending roll forming machine SX-UBM-625-330

Five Advantages Of Products

- Advantages of UBM architecture By using UBM vertical cold roller forming machine, a 1000 square meter steel structure building can be built in 24 hours. Using high speed production speed and panel bite ,10-12 people can make and install nearly 100 arched panels in a day.

- Low Cost As the speed increases, the costs of UBM buildings are lower than that of traditional buildings and prefabricated buildings.

- Field Manufacturing The UBM mobile factory is transported directly to the construction site, the building is made entirely on site. There is no additional costs to transport building components from the factory to the site.

- Move and access to remote areas UBM vertical cold roller molding machine installed on the trailer is easy to be towed to remote places by an ordinary vehicles and can be used immediately after arrival.

- No structural clamps, beams or trusses are required UBM arch is designed to be fully self-supporting and does not require a support structure like a standard steel frame building. Saving manpower A team of about 10 to 15 trained people can build a 1000 square meter building in a day. Users can build their beamless arch buildings with steel or aluminum, both of which have a series of color pre-coatings. We also stored most of the steel coils and immediately transported them to the construction site with the unit.

Product Details

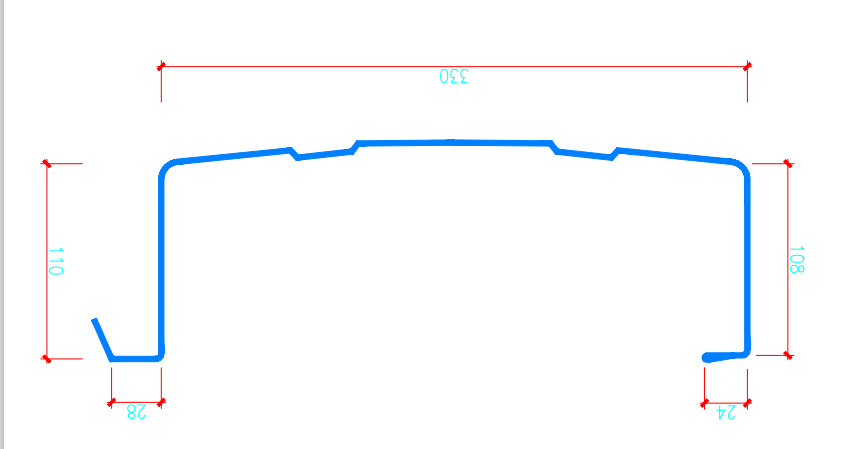

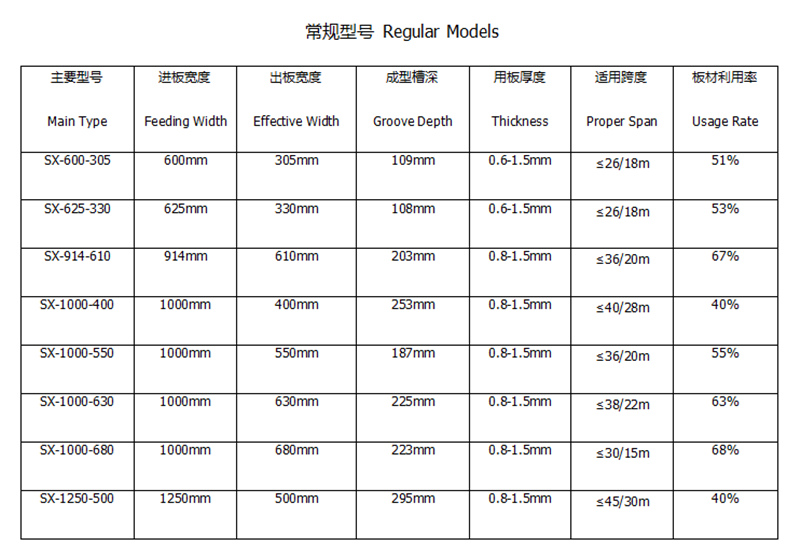

Vertical cold bending roll forming machine SX-UBM-625-330

Feeding width: 625 mm

Effective width: 330 mm

Usage Rate: 52.8 %

Applicable coil thickness: 0.8-1.5mm

Applicable span: ≤26/18 m

invention patent number: ZL 201010569504.7

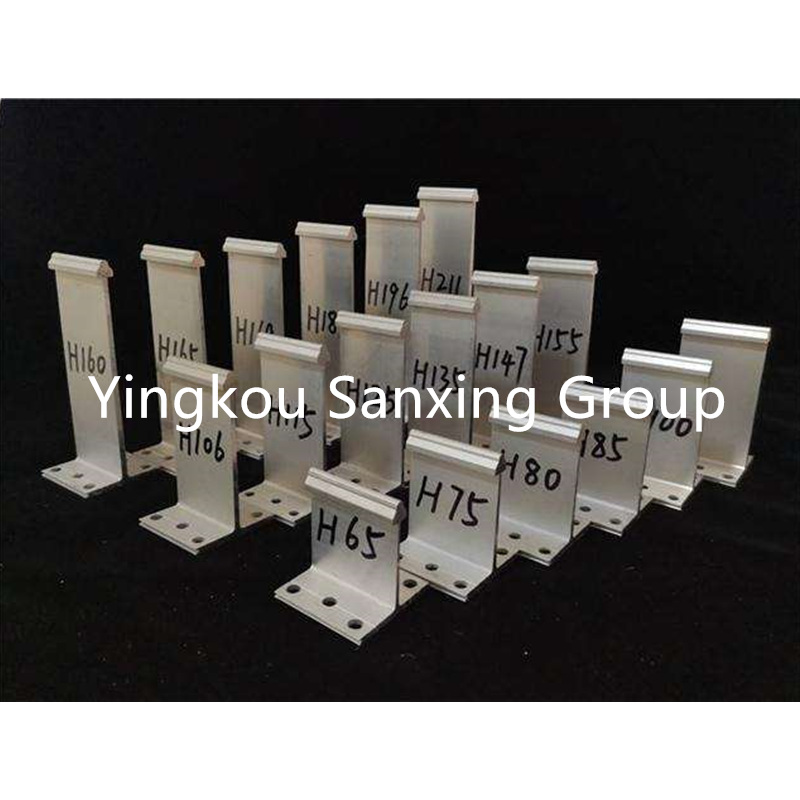

The main equipment produced by Sanxing: UBM machine, UBM120, UBM240, ultimate building machine, Roll forming machine, forming machine, mic machine, UCM machine, beamless roof machine, arch roof forming machine, arch roof machine, roll forming machinery, China span machine, SUBM machine

The UBM cold roll forming machine is a self-contained, trailer mounted mobile factory used for the production of steel buildings directly at a construction site. The building material is a steel coil stock. The roll forming machine is towed to the construction site where it is set up by a small crew adjacent to the building location. One set of the machines works in an entire production line, for forming, curving and cutting purposes.

The curved panels come in a traditional gable shape (straight side walls and a pitched roof), rounded double radius shape (straight side wall and broad curved roof section) or in the form of a circle arc with a fixed radius.

Finished panels are carried to an assembly area where they are connected together in groups of three using a fully patented and electrically powered seaming machine. The seamed connections are waterproof and require no bolts or other fasteners. After the three panels are assembled, they are lifted using a crane, and furnished by the builder. The panel section is then placed onto a foundation that has been prepared in advance. This process is repeated until the desired building length is achieved, of which there is no limit.

The interior building is finished as any other pre-engineered building is, and insulation, electricity, plumbing, lights, ventilators, heating and cooling systems, and partitions can be added.

UBM Vertical Type Cold Roll Forming Machine

UBM machine, UBM120, UBM240, ultimate building machine, Roll forming machine, forming machine, mic machine, UCM machine, beamless roof machine, arch roof forming machine, arch roof machine, roll forming machinery, China span machine, SUBM machine

Yingkou Sanxing Group

Contact Person: Rebecca Wang

Telephone: +86-13941746206

Landline: +86-417-2604444

Company Address: No.69 Hailan Street, Yingkou Area of China (Liaoning) Pilot Free Trade Zone

Factory Address: No.69 Hailan Street, Yingkou Area of China (Liaoning) Pilot Free Trade Zone

Website: www.sxmanufacturer.com

Previous: Vertical cold bending roll formin...