Products

Vertical cold bending roll forming machine SX-UMB-1250-500

Five Advantages Of Products

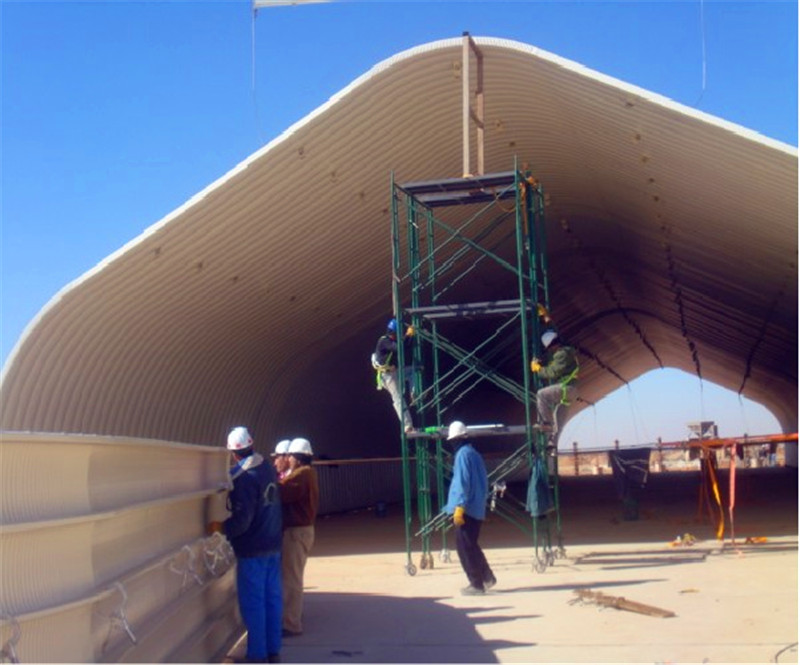

- Advantages of UBM architecture By using UBM vertical cold roller forming machine, a 1000 square meter steel structure building can be built in 24 hours. Using high speed production speed and panel bite ,10-12 people can make and install nearly 100 arched panels in a day.

- Low Cost As the speed increases, the costs of UBM buildings are lower than that of traditional buildings and prefabricated buildings.

- Field Manufacturing The UBM mobile factory is transported directly to the construction site, the building is made entirely on site. There is no additional costs to transport building components from the factory to the site.

- Move and access to remote areas UBM vertical cold roller molding machine installed on the trailer is easy to be towed to remote places by an ordinary vehicles and can be used immediately after arrival.

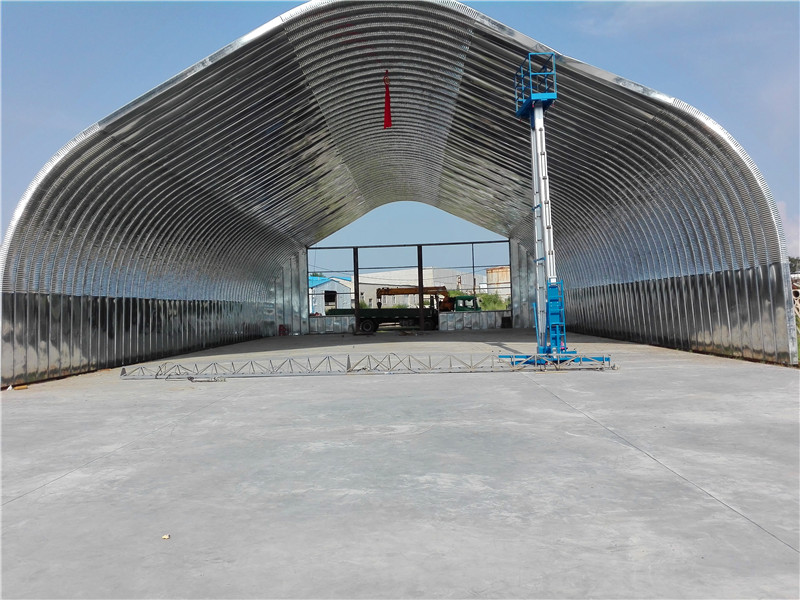

- No structural clamps, beams or trusses are required UBM arch is designed to be fully self-supporting and does not require a support structure like a standard steel frame building. Saving manpower A team of about 10 to 15 trained people can build a 1000 square meter building in a day. Users can build their beamless arch buildings with steel or aluminum, both of which have a series of color pre-coatings. We also stored most of the steel coils and immediately transported them to the construction site with the unit.

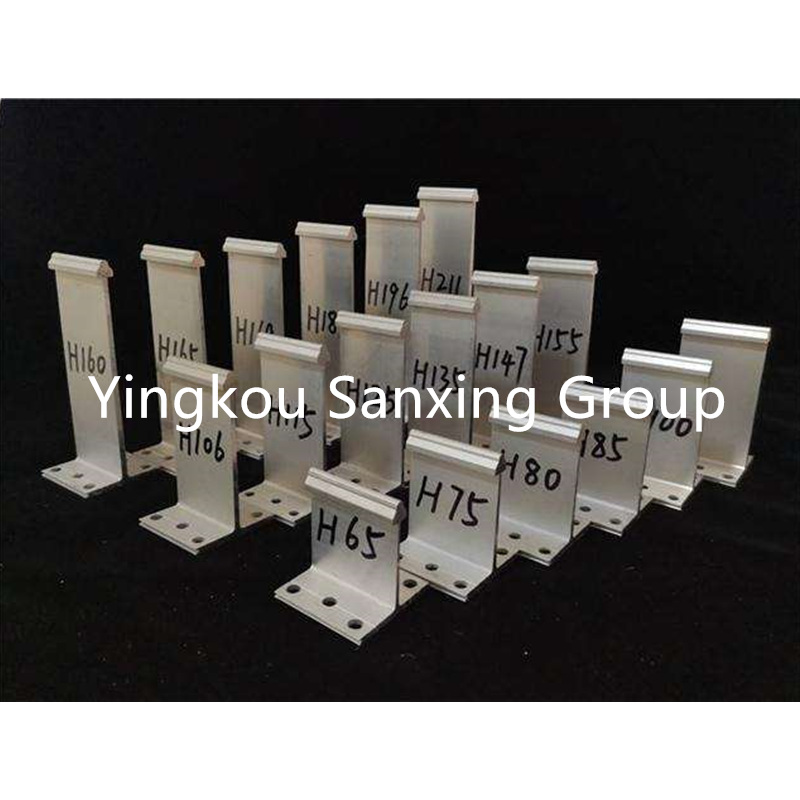

Product Details

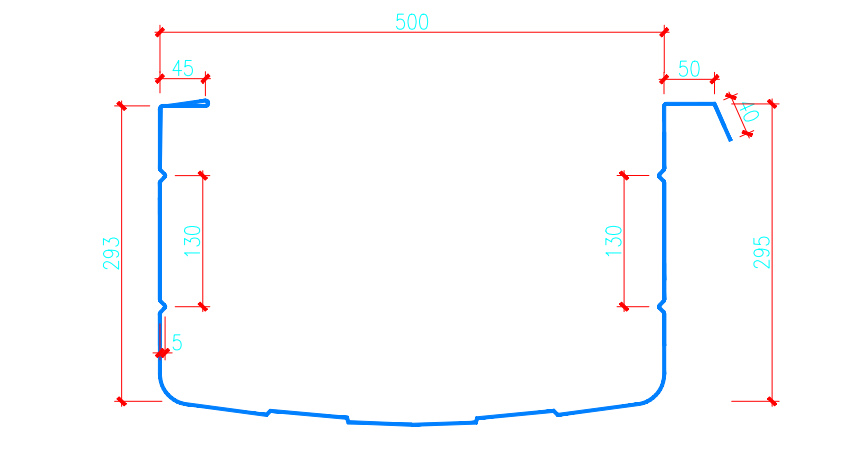

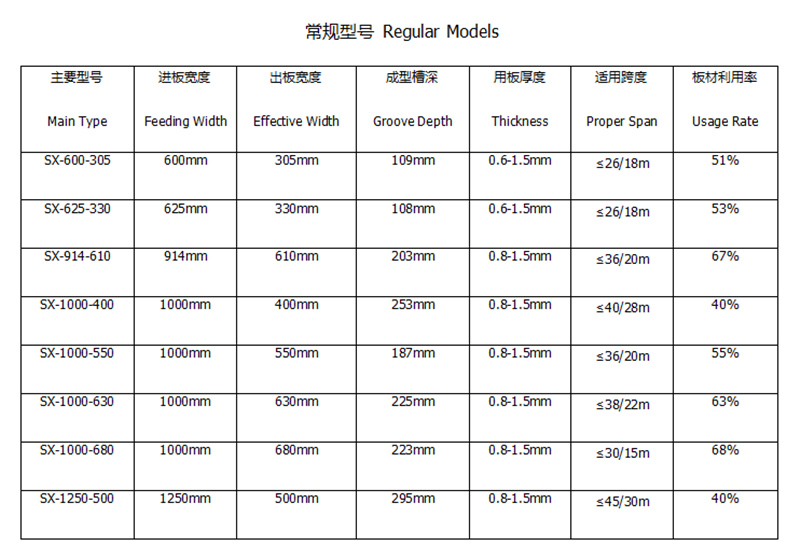

Vertical cold bending roll forming machine SX-UMB-1250-500

Feeding width: 1250 mm

Effective width: 500 mm

Usage Rate: 40%

Applicable coil thickness: 0.8-1.5mm

Applicable span: ≤45/30m

invention patent number: ZL 201010569504.7

The main equipment produced by Sanxing: UBM machine, UBM120, UBM240, ultimate building machine, Roll forming machine, forming machine, mic machine, UCM machine, beamless roof machine, arch roof forming machine, arch roof machine, roll forming machinery, China span machine, SUBM machine

Advantages of the SUBM Mobile Factory System

1. Fabrication of steel buildings on site with microprocessor precision and safety

2. Fast, durable and easy to operate

3. Operation is at 40-60% less than other methods.

4. Galvanized, pre-painted steel coils reduce logistics requirements up to 80%.

5. The SUBM is set up to produce panels within minutes of arriving at the construction site.

6. Panels are curved, and controlled by an on-board microprocessor.

7. Completed panels are carried to the assembly area.

8. Panels are seamed together in sections in preparation for lifting.

9. Panel sections are lifted and placed in a prepared foundation.

10. Panel sections are fit together, and joined using a patented seaming tool.

11. Hangers are placed during the construction process for easy installation of lights, sprinklers, duct work and other building components.

Generation I

Two Step Production

1. First step for straight panel

2. Second step for curved panel

Straight part: feeding --> forming --> cutting

Curving part: feeding --> curving

Generation II

This production process is a new one, and utilizes only a single step for both straight and curved panels. Compared to Generation I, the labor cost is reduced by up to 30% and the working speed at the project speed is improved by more than 20%.

Feeding --> Forming --> Cutting --> Curving --> Lifting

Generation III

With the use of a diesel truck and an 8T crane, the contractor can drive the truck directly to the project site. It takes only a single step to finish the panels needed, and no workers are needed to hold and carry the panels. When the panels are ready, the crane on the machine can easily lift and fix them in place. Compared to the Generation I, the labor cost is reduced by up to 80% and the working speed is improved by more than 70%.

Feeding --> forming --> cutting --> curving --> lifting

Yingkou Sanxing Group

Contact Person: Rebecca Wang

Telephone: +86-13941746206

Landline: +86-417-2604444

Company Address: No.69 Hailan Street, Yingkou Area of China (Liaoning) Pilot Free Trade Zone

Factory Address: No.69 Hailan Street, Yingkou Area of China (Liaoning) Pilot Free Trade Zone

Website: www.sxmanufacturer.com

Previous: Quonset Multiple Shape Building P...